Modelado Mecanicista y Experimentación in silico para la Predicción de la Vida de Anaquel en Productos Lácteos

DOI:

https://doi.org/10.17488/RMIB.45.2.6Palabras clave:

datos experimentales, regresión no lineal, simulaciones numéricas, sistemas no lineales variantes en el tiempo, vida de anaquelResumen

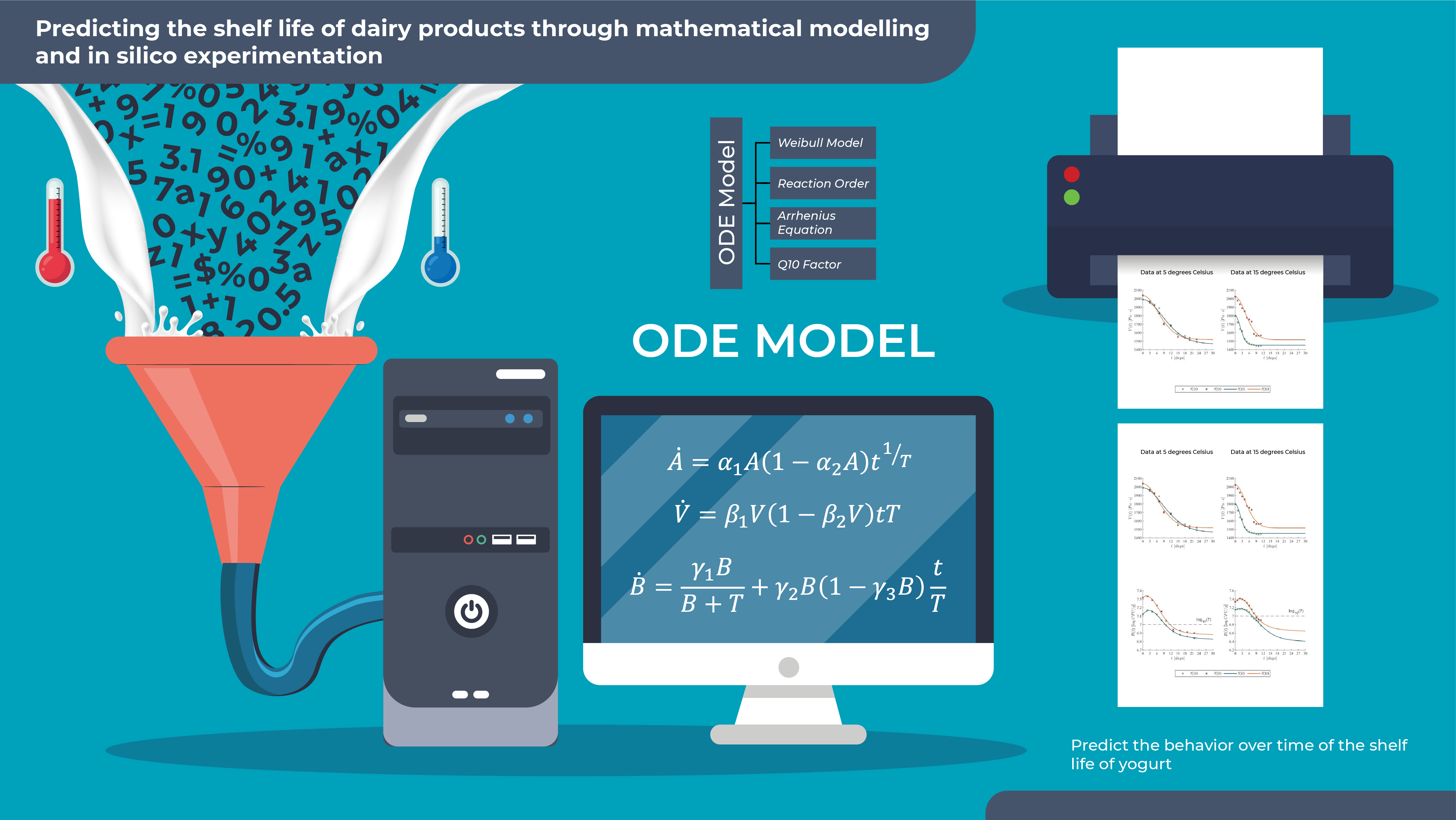

La conservación de alimentos como la leche, la carne y las verduras mediante la fermentación da como resultado productos como yogur, queso, encurtidos, salchichas y ensilados con una vida útil más prolongada en comparación con sus homólogos naturales sin procesar. El objetivo es formular un modelo matemático de ecuaciones diferenciales ordinarias (EDOs) de primer orden que tengan en cuenta los parámetros fisicoquímicos y microbiológicos que afectan la cinética de la biomasa [B(t)], la acidez [A(t)] y la viscosidad. [V(t)] en función de la temperatura en diferentes muestras de yogur. Para validar la eficacia del modelo para predecir la vida útil del yogur, comparamos los resultados de ajuste con métodos comúnmente empleados como el modelo de Weibull, el modelo de orden de reacción, la Ecuación de Arrhenius y el Factor Q10. Nuestra evaluación, basada en valores de R-cuadrada (R2) mayores a 0.95, demuestra la solidez del modelo propuesto. Además, se estimaron todos los parámetros junto con sus correspondientes intervalos de confianza del 95 %. El modelo matemático estima la dinámica de cada uno de los parámetros microbiológicos y fisicoquímicos los cuales ayudan a predecir el comportamiento sobre la vida de anaquel del yogur a diferentes temperaturas.

Descargas

Citas

N.-N. Zhi, K. Zong, K. Thakur, J. Qu, et al., “Development of a dynamic prediction model for shelf life evaluation of yogurt by using physicochemical, microbiological and sensory parameters,” CyTA - J. Food, vol. 16, no. 1, pp. 42–49, Jan. 2018, doi: https://doi.org/10.1080/19476337.2017.1336572

S. Sarkar, “Shelf‐life extension of cultured milk products,” Nutr. Food Sci., vol. 36, no. 1, pp. 24–31, Jan. 2006, doi: https://doi.org/10.1108/00346650610642160

C. Paulo Vieira, M. Pereira da Costa, B. da Silva Frasão, V. L. de Melo Silva, R. Vilela de Barros Pinto Moreira, Y. E. Chifarelli de Oliveira Nunes, C. A. Conte-Junior, “Nondestructive prediction of the overall quality of cow milk yogurt by correlating a biogenic amine index with traditional quality parameters using validated nonlinear models,” J. Food Compos. Anal., vol. 84, art. no. 103328, Dec. 2019, doi: https://doi.org/10.1016/j.jfca.2019.103328

F. Al-Rimawi, M. Alayoubi, c. Elama, M. Jazzar, and A. Çakıcı, “Use of cinnamon, wheat germ, and eucalyptus oils to improve quality and shelf life of concentrated yogurt (Labneh),” Cogent Food Agric., vol. 6, no. 1, art. no. 1807810, 2020, doi: https://doi.org/10.1080/23311932.2020.1807810

M. Mataragas, V. Dimitriou, P. N. Skandamis, and E. H. Drosinos, “Quantifying the spoilage and shelf-life of yogurt with fruits,” Food Microbiol., vol. 28, no. 3, pp. 611–616, May 2011, doi: https://doi.org/10.1016/j.fm.2010.11.009

Y. Shao, Y. He, and S. Feng, “Measurement of yogurt internal quality through using Vis/NIR spectroscopy,” Food Res. Int., vol. 40, no. 7, pp. 835–841, Aug. 2007, doi: https://doi.org/10.1016/j.foodres.2007.01.014

O. S. Papadopoulou, A. A. Argyri, V. Kounani, C. C. Tassou, and N. Chorianopoulos, “Use of Fourier Transform Infrared Spectroscopy for Monitoring the Shelf Life and Safety of Yogurts Supplemented With a Lactobacillus plantarum Strain With Probiotic Potential,” Front. Microbiol., vol. 12, art. no. 678356, Jun. 2021, doi: https://doi.org/10.3389/fmicb.2021.678356

A. G. Cruz, E. H. M. Walter, R. Silva Cadena, J. A. F. Faria, H. M. A. Bolini, H. P. Pinheiro, A. S. Sant’Ana, “Survival analysis methodology to predict the shelf-life of probiotic flavored yogurt,” Food Res. Int., vol. 43, no. 5, pp. 1444–1448, Jun. 2010, doi: https://doi.org/10.1016/j.foodres.2010.04.028

J. Stangierski, D. Weiss, and A. Kaczmarek, “Multiple regression models and Artificial Neural Network (ANN) as prediction tools of changes in overall quality during the storage of spreadable processed Gouda cheese,” Eur. Food Res. Technol., vol. 245, no. 11, pp. 2539–2547, Nov. 2019, doi: https://doi.org/10.1007/s00217-019-03369-y

S. Goyal and G. K. Goyal, “Shelf Life Estimation of Processed Cheese by Artificial Neural Network Expert Systems,” J. Adv. Comput. Sci. Technol., vol. 1, no. 1, pp. 32-41, 2012. [Online]. Available: https://www.sciencepubco.com/index.php/JACST/article/view/10/439

J. F. Oblitas-Cruz and J. A. Sánchez-González, “Application of Weibull analysis and artificial neural networks to predict the useful life of the vacuum packed soft cheese,” Rev. Fac. Ing. Univ. Antioquia, no. 82, pp. 53–59, Mar. 2017, doi: https://doi.org/10.17533/udea.redin.n82a07

R. R. B. Singh, A. P. Ruhil, D. K. Jain, A. A. Patel, and G. R. Patil, “Prediction of sensory quality of UHT milk – A comparison of kinetic and neural network approaches,” J. Food Eng., vol. 92, no. 2, pp. 146–151, May 2009, doi: https://doi.org/10.1016/j.jfoodeng.2008.10.032

X. Dong, Q. Li, D. Sun, X. Chen, and X. Yu, “Direct FTIR Analysis of Free Fatty Acids in Edible Oils Using Disposable Polyethylene Films,” Food Anal. Methods, vol. 8, no. 4, pp. 857–863, 2015, doi: https://doi.org/10.1007/s12161-014-9963-y

I. Ahmad, M. Hao, Y. Li, J. Zhang, Y. Ding, and F. Lyu, “Fortification of yogurt with bioactive functional foods and ingredients and associated challenges - A review,” Trends Food Sci. Technol., vol. 129, pp. 558–580, Nov. 2022, doi: https://doi.org/10.1016/j.tifs.2022.11.003

W. F. Castro, A. G. Cruz, M. S. Bisinotto, L. M. R. Guerreiro, et al., “Development of probiotic dairy beverages: Rheological properties and application of mathematical models in sensory evaluation,” J. Dairy Sci., vol. 96, no. 1, pp. 16–25, 2013, doi: https://doi.org/10.3168/jds.2012-5590

E. Al-Kadamany, M. Khattar, T. Haddad, and I. Toufeili, “Estimation of shelf-life of concentrated yogurt by monitoring selected microbiological and physicochemical changes during storage,” LWT – Food, Sci. Techol., vol. 36, no. 4, pp. 407–414, 2003, doi: https://doi.org/10.1016/S0023-6438(03)00018-5

E. Al-Kadamany, I. Toufeili, M. Khattar, Y. Abou-Jawdeh, S. Harakeh, and T. Haddad, “Determination of shelf life of concentrated yogurt (labneh) produced by in-bag straining of set yogurt using hazard analysis,” J. Dairy Sci., vol. 85, no. 5, pp. 1023–1030, 2002, doi: https://doi.org/10.3168/jds.s0022-0302(02)74162-3

R. Arboretti, E. Barzizza, L. Salmaso, R. Ceccato, et al., “Shelf-life prediction: A comparison of methods,” Electron. J. Appl. Stat. Anal., vol. 15, no. 3, pp. 527–552, 2022, doi: https://doi.org/10.1285/i20705948v15n3p527

M. Mahendradattal, F. Bastianl, Kasmiati, and N. Amaliah, “Shelf-life prediction of seasoning powder made from whole fermented fish (peda) by using Arrhenius method,” in Procc. of International Seminar Current Issues and Challenges in Food Safety, 2007, pp. 222–232.

R. Sánchez, F. Cerrón, J. Canchuricra, and M. Aquino, “Vida util del yogur bionatural usando el metodo del valor Q10 y analisis de supervivencia,” Tecnol. Alimentos, pp. 1-9, 2013.

I. Saguy and M. Karel, “Modelling of quality deterioration during food processing and storage,” Food Technol., vol. 34, no. 2, pp. 78-85, 1980.

P. S. Taoukis, T. P. Labuza, and I. S. Saguy, “Kinetics of Food Deterioration and Shelf-Life Prediction,” in Handbook of food engineering practice, United State of America: CRC Press, 1997, pp. 367–407.

R. M. Salinas-Hernández, G. A. González-Aguilar, and M. E. Tiznado-Hernández, “Utilization of physicochemical variables developed from changes in sensory attributes and consumer acceptability to predict the shelf life of fresh-cut mango fruit,” J. Food Sci. Technol., vol. 52, no. 1, pp. 63–77, 2015, doi: https://doi.org/10.1007/s13197-013-0992-0

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2024 Yolocuauhtli Salazar-Muñoz, Paul A. Valle, Emmanuel Rodríguez, Manuel F. Alvarado Ontíveros

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Una vez que el artículo es aceptado para su publicación en la RMIB, se les solicitará al autor principal o de correspondencia que revisen y firman las cartas de cesión de derechos correspondientes para llevar a cabo la autorización para la publicación del artículo. En dicho documento se autoriza a la RMIB a publicar, en cualquier medio sin limitaciones y sin ningún costo. Los autores pueden reutilizar partes del artículo en otros documentos y reproducir parte o la totalidad para su uso personal siempre que se haga referencia bibliográfica al RMIB. No obstante, todo tipo de publicación fuera de las publicaciones académicas del autor correspondiente o para otro tipo de trabajos derivados y publicados necesitaran de un permiso escrito de la RMIB.